- Healthy Returns: Pfizer pulls sickle cell disease drug from markets – here’s why it matters

- With Hurricane Helene disrupting travel, here’s what fliers need to know

- Tesla set to report Q3 deliveries ahead of robotaxi event

- Port strike could reignite inflation, with larger economic impact dependent on how long it lasts

- 'Who's a good boy?' Humans use dog-specific voices for better canine comprehension

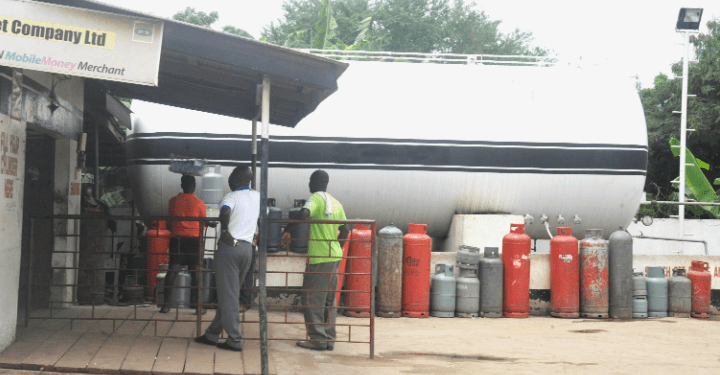

What do you believe is the single most important factor driving up the cost of living in Nigeria?

Soda production process eliminates CO₂ emissions

Fraunhofer researchers and their partners have developed an innovative and eco-friendly method of producing soda, essential for a wide range of industries, in the Green Soda project. The process is based on bipolar electrodialysis of brine. Ion exchange processes and the addition of carbon dioxide result in green soda. The technology will also help to strengthen manufacturing in Germany as an industrial location.

Sodium carbonate, also known as soda ash, is an essential material used in many different industrial sectors. It is used to make paper, preserve foods, manufacture glass and neutralize acids.

It is also found in private households, where it is the main ingredient in baking powder and is used as a stain remover and drain cleaner. And the numbers reflect this: The German chemical industry association Verband der chemischen Industrie (VCI) indicates that some 2.1 million metric tons of soda ash and sodium bicarbonate were produced in Germany alone in 2023.

The issue is that production of soda emits large amounts of carbon dioxide—800 kilograms per metric ton. Salty wastewater is another byproduct, increasing the salinity of water bodies.

The solution is a sustainable new production process that generates no climate-damaging CO 2 emissions or saline wastewater.

- September 30, 2024

Britain's last coal-fired power station closes

- September 27, 2024

Solar panels soon may power and protect apple orchards

- October 2, 2024

Tesla set to report Q3 deliveries ahead of robotaxi event

- September 29, 2024

Nepal dam-building spree powers electric vehicle boom

Subscribe to our mailing list to get the new updates!

Subscribe our newsletter to stay updated

Thank you for subscribing!